PP pleated cartridge filter is constructed by 100% polypropylene media providing a wide range of chemical compatibility. The polypropylene cartridge filters include 3 to 4 layers of membrane. The multi layers membranes structure enables a graded filtration pore sizes and increases the dirt-holding capacity of the PP pleated cartridge filters.

High surface area design provides excellent flow capacity and long service life wid process applications.

Features

- Free of binders, additives and lubricants

- Constructed by advanced thermal welding techniques to seal all components

- May be autoclaved (121℃,30 minutes) or in steam sterilized(121℃,30 minutes) for a maximum accumulated exposure of 10 hours.

Application

- Pharmaceuticals, APIs, biologics

- Plating solutions

- Fine chemicals

- Food & beverages, wine, beer, mineral water

- Semi-conductor, LCD display, discs

10″ PP Pleated Filter Cartridge

| Construction Material | Filter Media | Polypropylene |

| Support Layers | Polypropylene | |

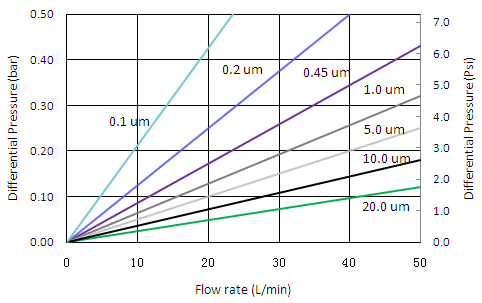

| Micron Rating | 0.1, 0.2, 0.45, 0.65, 1.0, 2.0, 3.0, 5.0, 10, 30, 40, 50, 70, 100μm | |

| Inner Core | Polypropylene | |

| Outer Cage & End Caps | Polypropylene | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Dimensions | Outer Diameter | 69mm (2.75″) |

| Inner Diameter | 33mm (1.30″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.65㎡ per 10″ | |

| Operating Conditions | Normal Operating Temp. | Up to 55℃(131℉) |

| Max. Operating Temp. | 80℃(172℉) at △P≤1.0bar(14psi) | |

| Normal Flow Direction | 4.2bar(60psi) at 25℃(77℉) | |

| Reverse Flow Direction | 2.1bar(30psi) at 25℃(77℉) | |

| pH Range | 1~13 | |

| Sterilization | Not recommended | |

| Cartridge Safety | Endotoxin | ﹤0.25 EU/ml |

| Extractables | 0.03g/10″ |

| Type | Micron Ratings | Length | O-ring | End Cap Option |

| PF PP Pleated Filter Cartridge |

02 – 0.2μm | 10 – 10″ 20 – 20″ 30 – 30″ 40 – 40″ Other customized sizes |

S – Silicone E – EPDM V – Viton W – Teflon encapsulated viton |

0 – flat gasket DOE 5 – 2-222 flat 6 – 2-226 flat 8 – 2-222 fin 9 – 2-226 fin |

| 045 – 0.45μm | ||||

| 1 – 1μm | ||||

| 2- 2μm | ||||

| 3- 3μm | ||||

| 5 – 5μm | ||||

| 10 – 10μm | ||||

| 30 – 30μm | ||||

| 40 – 40μm | ||||

| 70 – 70μm |