Utter OM Series Pleated Filter cartridges are manufactured to fit exact standards and are used in the most demanding industrial applications. Our filter cartridges are manufactured in a range of length options and micron ratings. This filters media has a fixed pore construction of high quality fibers. The combination of surface and depth filtration help provide a long service life. With the use of premium quality filter fabrics, our pleated filter cartridges have superior flow characteristics with a very low pressure drop compared to depth media of similar micron rating. The advantages of this filter is that it has a smaller filter vessel, smaller footprint and lower capital investments. Long cartridge lifetime means lower operational costs, less work changing the cartridges and less waste.Our thermal welded construction provides safety against high temperature oily waters, solvents, acid, and diesel fuels.

Features

- Oil exploitation

- Mine exploitation

- Chemical

- Process water filtration

| Dimension |

[ OD ]:Ø 64mm

[ ID ]:Ø 28mm

[ Length ]:30 ”,40 ”

|

| Material

of Constructions |

[ Media ]:PP,PET, Glass Fiber

[ End Cap Material ]: PP

[ Center Core ]: PP

[ Outer Cage ]: PP

[ Sealing ]:Silicone,EPDM,NBR,Viton

[ End Cap Types ]:222/Flat End

|

| Performance | Operating Pressure and temperature:

The pleated cartridge construction will withstand differentia Pressures up to 60 PSI(4Bar) at ambient temperature

The optimum changeout differential pressure is 35psi(2.5Bar) up to 52°C

Service condition:

500KPa(5Bar)by 20°C

300KPa(3Bar)by 65°C

Beta:

5000(99.98% removal efficiency) for glass fiber media Construction: Fully thermal welded

|

| Code | Filter Media | Length | Removal Rating | O-Ring |

| OM | G = PP S = Glass Fiber Z = PET |

30 = 30” (762mm) 40 = 40″ (1016mm) |

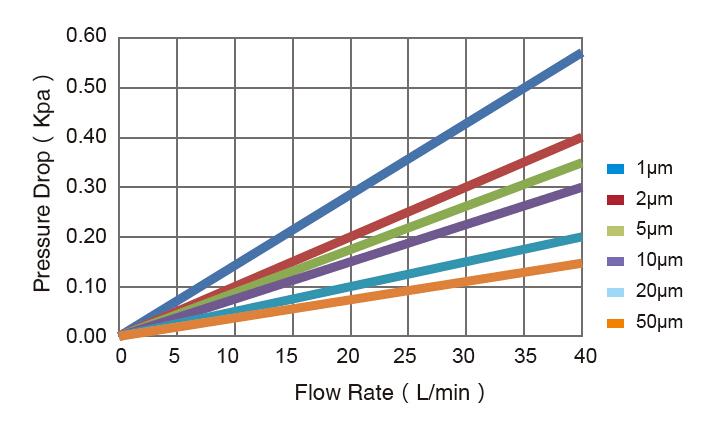

1 = 1μm 2 = 2μm 5 = 5μm 10 = 10μm 20 = 20μm 50 = 50μm |

S = Silicone E = EPDM B = NBR V = Viton |