PES membrane pleated filter cartridges have special feature of low protein binding and therefore ideal for applications requiring critical cleanliness such as biological, pharmaceutical and microelectronic processes. The incorporation of asymmetric PES membranes ensures consistent particle retention efficiency, low pressure drop and exceptional service life.

Features

- Hydrophilic and asymmetric PES membranes provide excellent flow capacity and long service life while maintaining maximum filtration performance

- Low protein binding makes GDS an ideal option for processes requiring critical cleanliness

- Wide chemical compatibility across a wide range of liquid processes

- 100% integrity tested

- May be autoclaved (121℃, 30 minutes) or steam sterilized (125℃, 30 minutes) for a maximum accumulated exposure of 10 hours

Application

- Sterile filtration for water, mineral water, wine, beer and other beverages

- Ultrapure water and disk, display, multi silicon process water in electronic

- Fine chemicals, water process

- API, LPV, blood serum, biologicals, buffers and other pharmaceuticals

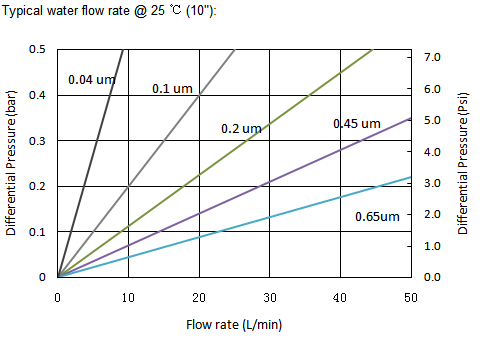

10″ Polyethersulfone Membrane Pleated Filter Cartridge Flow Rate

| Construction Material | Filter Media | Asymmetric PES Membrane |

| Support Layers | Polypropylene | |

| Micron Rating | 0.04, 0.1, 0.2, 0.45, 0.65, 0.85, 1.2μm | |

| Inner Core | Reinforced Polypropylene | |

| Outer Cage & End Caps | Reinforced Polypropylene | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Dimensions | Outer Diameter | 69mm (2.75″) |

| Inner Diameter | 33mm (1.30″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.65㎡ per 10″ | |

| Operating Conditions | Normal Operating Temp. | Up to 60℃(℉) |

| Max. Operating Temp. | 85℃(185℉) at △P≤1.0bar(14psi) | |

| Normal Flow Direction | 4.2bar(60psi) at 25℃(77℉) | |

| Reverse Flow Direction | 2.1bar(30psi) at 25℃(77℉) | |

| pH Range | 2~13 | |

| Sterilization | Steam sterilization for 30 minutes at 121±2℃ cumulative time: 8 hours | |

| Cartridge Safety | Endotoxin | ﹤0.25 EU/ml |

| Extractables | 0.03g/10″ |

| Type | Micron Ratings | Length | O-ring | End Cap Option |

| PES | 01 – 0.1μm 02 – 0.2μm 045 – 0.45μm 1 – 1μm |

05 – 5″ 10 – 10″ 20 – 20″ 30 – 30″ 40 – 40″ Other customized sizes |

S – Silicone E – EPDM V – Viton W – Teflon encapsulated viton |

0 – flat gasket DOE 5 – 2-222 flat 6 – 2-226 flat 8 – 2-222 fin 9 – 2-226 fin |