Utter’s lenticular filter modules are used in a broad range of applications. They find multiple applications in many beverage duties, such as wine, beer, spirits and soft drinks. In common with filter sheets used in a filter press the grade of lenticular module is chosen to specifically suit the application.

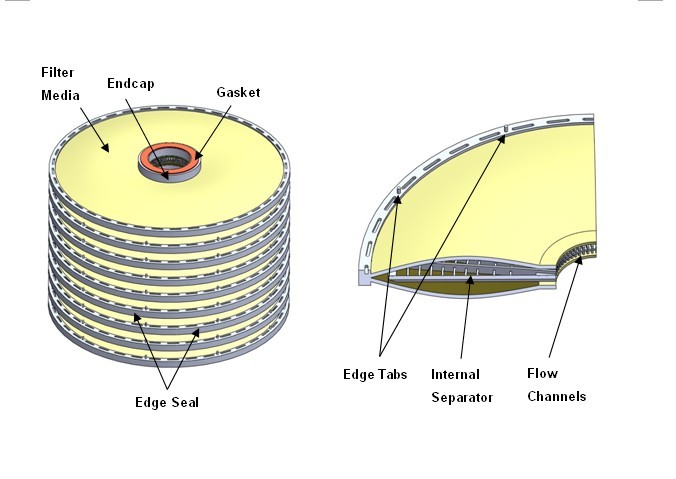

Utter lenticular filters are essentially composed of depth filter media supported on a polypropylene skeleton and supplied in modular form. The lenticular modules are either 8″, 12″(300mm) or 16″(400mm) diameter. Each module is made up of multiple cells, normally 16, but can be adjusted to suit specific requirements. Each cell consists of 2 discs of filter media formed around an internal all polyprolylene matrix. The outer edges of the media are sealed with an injection moulded polypropylene strip. These modules can then be used in a single or multiple housings, stacked end to end up to 4 high.

Features

- Washable under certain conditions, resulting in high total throughput

- Easy and reliable handling rigid external clips prevent damage of the filter sheet during module loading and uploading

- No filter sheet deformities after heat treatment

- No adverse effects to filter sheets when in contact with hot sanitization or process filtration

- Mechanical filtration due to cellulose

Application

- Chemical: paints, resins, varnishes, solvents, inks

- Pharmaceutical: gelatine, serums, saline solutions

- Cosmetics: gels, hair sprays, nail polishes

- Beverages: sugar-syrup, fruit juices, wine, beer, spirits

- Foods: pickling solution, rinsing water

| Construction Material | Depth Filter Sheet | Cellulose fibers, resins, perlite, natural diatomaceous earths |

| Core | Polypropylene | |

| O-ring | Silicone, EPDM, Viton | |

| Dimensions | Outer Diameter | 8″, 12″, 16″ |

| Micron Rating | 0.3, 0.8, 1.0, 2.5, 5.0μm | |

| Type | Micron Ratings | OD | Seal Material | End Cap Type |

| LFM – Lenticular Filter Module |

03 – 0.3μm 08 – 0.8μm 1 – 1μm 2 – 2μm 5 – 5μm |

12 – 12″ 16 -16″ |

S – Silicone E – EPDM V – Viton |

D – DOE with gasket S – SOE with double o-ring |