Utter’s PTFE Membrane filter cartridges deliver superior removal efficiency by the character of fixed pore construction. The incorporation of hydrophobic PTFE membranes with PP construction serves economic alternatives to all fluropolymer filter cartridges. Featuring broad chemical compatibility and excellent temperature endurance. Those cartridges are suitable for less aggressive processes and applications requiring high cleanliness.

Feature

- Economic alternatives to all fluropolymer filter cartridges in less aggressive applications

- Satisfy various chemical processes by broad chemical compatibility and excellent temperature endurance

- Provide superior and consistent removal efficiency by the character of fixed pore construction

- 100% integrity tested

- May be autoclaved (121℃, 30 minutes cycles) or steam sterilized (125℃, 30 minutes cycles) for a maximum accumulated exposure of 10 hours

Application

RO/DI process, semiconductor, storage tank vents, solvents, process gases, photoresists, etchants, chemicals, pharmaceutical, food & beverage

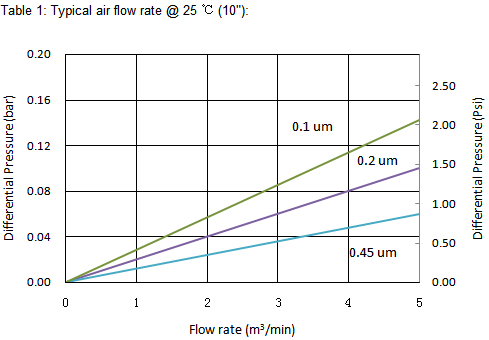

10″ Hydrophobic PTFE Membrane Filter Cartridges Flow Rate

| Construction Material | Filter Media | Hydrophobic PTFE membrane |

| Support Layers | Polypropylene | |

| Micron Rating | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0μm | |

| Inner Core | Reinforced Polypropylene/stainless steel | |

| Outer Cage & End Caps | Reinforced Polypropylene | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Dimensions | Outer Diameter | 69mm (2.75″) |

| Inner Diameter | 33mm (1.30″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.65㎡ per 10″ | |

| Operating Conditions | Normal Operating Temp. | Up to 65℃(140℉) |

| Max. Operating Temp. | 90℃(194℉) at △P≤1.0bar(14psi) | |

| Normal Flow Direction | 4.2bar(60psi) at 25℃(77℉) | |

| Reverse Flow Direction | 2.1bar(30psi) at 25℃(77℉) | |

| pH Range | 1~14 | |

| Sterilization | Steam sterilization for 30 minutes at 121±2℃ 100cyles autoclave 30 minutes (optional) |

|

| Cartridge Safety | Endotoxin | ﹤0.25 EU/ml |

| Extractables | 0.03g/10″ |

| Type | Micron Ratings | Filter Media | Length | O-ring | End Cap Option |

| FPTFE | 01 – 0.1μm 02 – 0.2μm 045 – 0.45μm 1 – 1μm |

F – Hydrophilic PTFE | 05 – 5″ 10 – 10″ 20 – 20″ 30 – 30″ 40 – 40″ Other customized sizes |

S – Silicone E – EPDM V – Viton W – Teflon encapsulated viton |

0 – flat gasket DOE 5 – 2-222 flat 6 – 2-226 flat 8 – 2-222 fin 9 – 2-226 fin |