String Wound Filter Cartridges

Utter string wound filter cartridges are manufactured by computer modeling process which optimizes the filter cartridges geometrically and maximizes the use of cartridge surface area by the diamond-shaped depth filtration cones.

Features

- Continuous stand winding process provides consistent performances of high dirt holding capacity, long service and high flow rate.

- Customized patterns and spacing offered to adapt to your specialized applications.

- With 6 media selections and 13 micron ratings.

- All end caps are available to fit your filter housing.

- Standard diameters are 2.5 & 4 inches

- Standard lengths from 9.75 up to 40 inches

Application

- Prefiltration for pure water system

- Prefiltration for pharmaceutical and chemical solution

- Process and waste water prefiltration in electronics industry

- Wine, beer, mineral water, pure water, beverage filtration

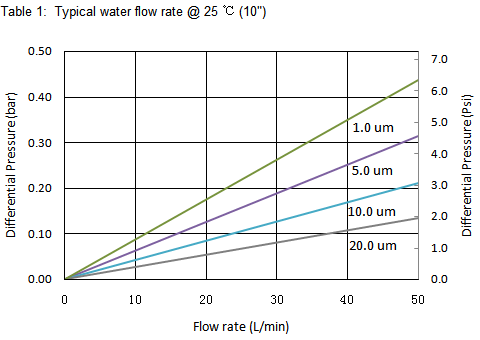

10″ String Wound Filter Cartridge Flow Rate

| Construction Material | Filter Media | Polypropylene/Bleached Cotton/Glass Fiber |

| Micron Rating | 1.0, 5.0, 10, 20μm | |

| Inner Core | Polypropylene or stainless steel | |

| O-ring | Silicone, Nitrile, EPDM, Viton, Teflon | |

| Filtration Efficiency | ≥80% | |

| Dimensions | Outer Diameter | 63mm (2.5″)/114mm(4.5″) |

| Inner Diameter | 28mm (1.10″) | |

| Length | 5″, 10″, 20″, 30″, 40″ | |

| Filtration Area | 0.4㎡ per 10″ | |

| Operating Conditions | Max.Operating Temp. | |

| Polypropylene | 80℃(176℉) at △P≤1.0bar(14psi) | |

| Bleached Cotton | 50℃(300℉) at △P≤1.0bar(14psi) | |

| Max.Differential Pressure | ||

| Polypropylene | 4.0bar(58psi) at 25℃(77℉) | |

| Bleached Cotton | 5.0bar(72psi) at 25℃(77℉) | |

| pH Range | 1~13 | |

| Sterilization | Not recommended |

| Type | Filter Media | Micron Rating | Core Material | Nominal Length |

| SW | P-Polypropylene C-Cotton G-Glass Fiber |

1-1μm 5-5μm 10-10μm 20-20μm 30-30μm 50-50μm |

P-Polypropylene 4-SUS304 6-SUS316L |

10-10″ 20-20″ 30-30″ 40-40″ |